Sustainability

Providing luxury with principles.

At Translux, we are committed to fostering a sustainable future through investment and responsible, sustainable practices.

By integrating these sustainable practices into our daily operations, we strive to make a positive impact on the environment, and contribute to a greener, more sustainable future.

Strategic depots & fleet

With established offices and depots throughout Europe, our extensive and varied fleet is strategically located to significantly reduce long-distance movements and emissions.

Our strong European subsidiary network offers our clients shooting in Europe, substantial savings on travel costs and greatly reduces their production’s carbon footprint, whilst providing benefits from local spend tax incentives and rebates.

Translux Fleet

Bespoke Combinations

We have pioneered new technology which allows Tech Trucks to tow facilities and technical trailers rather than travel separately. This reduces the number of vehicles required for unit moves and consequently nearly halves emissions for such travel.

Euro 6/ULEZ

We are the largest provider of Euro 6 Trucks in the Film & Television Industry.

Euro 6 is the highest emission standard vailable, reducing CO2 emissions and allowing our vehicles to enter the Ultra-Low Emission Zones in London and other cities in the UK and Europe.

Vehicle Maintenance

With our in-house truck workshop, trailer workshop, builds department and spray booth, we are entirely self-sufficient for the maintenance of our UK and European fleet.

Compliance

Translux has a comprehensive truck maintenance department with highly qualified mechanical technicians that are responsible for carrying out maintenance inspections every 10 weeks.

As per the terms of our Operator’s Licence – this legally required vehicle inspection tests their braking systems, tyres, engines, and all moving parts to ensure correct function. This guarantees not only the vehicles safety, but also its optimum performance and fuel efficiency.

Additionally, before leaving the depot for a project, all equipment in our fleet undertakes a stringent Pre-delivery Inspection (PDI) check. This check allows Translux to ensure that each vehicle meets Health & Safety, and Legal Compliance requirements, and ensures it will leave the smallest possible carbon footprint on location.

Amongst other things, these PDIs include:

- Ensuring all areas of the vehicle are functioning correctly. This reduces the likelihood of breakdowns/problems that could delay filming or require Translux maintenance personnel to travel and solve the problem on location. This not only offers a financial benefit to clients, but also offers a significant environmental benefit as delays and on-site vehicle repair can significantly increase their carbon footprint.

- Ensuring only what the client needs for the project has been loaded onto the vehicle to avoid carrying unnecessary weight.

- Confirming the tyres are inflated to the correct pressure to avoid unnecessary strain on the engine.

Meet the power team

Reducing on-set emissions by utilising Battery Energy Storage Systems (BESS) and Hydrotreated Vegetable Oil (HVO)

Pramac LX 60/100Kva LFP Hayashi

MGTP 100KVA Stage 5 Generator

HVO FUEL

Remote Control & Telematics

HVO Fuel

- With sustainability at the forefront of global consciousness, one would be hard pressed to find an industry that has not adopted measures to “go greener”. This can certainly be said of the Film & Television industry, at times notorious for its carbon footprint and impact on our environment. Fortunately, however, we have recently seen a concerted effort within the industry to shift to more environmentally friendly productions.

- As the leading facilities and locations provider for Film & Television in the UK and Europe, it seems fitting that we lead by example. As such, thanks to a lot of hard work behind the scenes, we can proudly say that, every one of our trucks departing from our Head Office will be fuelled by HVO.

- HVO is 100% biodegradable and renewable, reducing greenhouse gas emissions by up to 90% - statistics that cannot be ignored. Performance-wise, the fuel maintains its efficiency, even in cold weather, and will improve the cleanliness of our fleet’s engines, furthering their overall sustainability.

- Whilst this is by no means the end of our journey to net zero, it is a huge step in the right direction, and we are excited to continue facilitating the Film & Television industry as we move into a greener future together.

Generators & Hybrid Power Solutions by Translux

Translux offer a market-leading Pramac LX 60/100Kva LFP off-grid battery pack, combined with a MGTP 100KVA Super Silent Generator.

This Battery Energy Storage System (BESS) is one of the most cost-effective and sustainable methods to store power for use on-demand.

Energy call-off is automatically managed from any, or all, energy sources to ensure the highest efficiency, least maintenance, and most sustainable results are achieved.

The PRAMAC LX 60/100Kva LFP off-grid battery pack is fully supported during periods of high demand by the MGTP 100KVA Stage 5 generator, which is supplied with complete remotely accessed Telematic Monitoring Systems. This allows real-time monitoring and maintenance to be fulfilled from any location throughout the world.

These generators achieve Stage 5 performance status by utilising HVO fuels and ensuring the most efficient, and lowest maintenance operations.

PRAMAC battery packs act as a universal energy storage system which are suitable for a wide range of applications.

They provide reliable energy in the most economical and environmentally friendly way, thanks to their innovative features and versatility. Their state-of-theart technology, such as the lithium-ion deep cycle battery module, guarantees high energy density, longlife, and excellent safety.

Additionally, the generators’ intuitive touch-screen control panel allows for quick and easy monitoring and performance management, whilst in the unlikely event of a power failure, the system can automatically draw from alternative generators to restore power and limit potential disruptions.

Ultra Silenced Event Ready 100KVA Diesel Generator MGTP 100 USKH-5

Features & Benefits:

- 100kVA 3ph (400V): Plenty of power to meet the demands of small to medium production hire.

- Linz Alternator: Heavy-duty and proven reliability.

- Kohler diesel engine (Stage 5): World-class performance and water-cooled.

- HVO fuel approved: Suitable to run off either diesel, HVO or a mixture of both fuels.

- Exclusive MHM-Gen engine protection shutdown system: In the case of low fuel, low oil pressure, high engine temp and battery charge failure.

- 3-way fuel valve: Easy connectivity to an external fuel tank.

- 12V battery isolator switch: Reduces flat battery breakdowns.

- Emergency stop button: A must on any UK site.

- Central lifting eye and fork pockets: Flexible and safe lifting on site.

- Variable RCD: Flexible protection.

- Fully bunded base (110%): To retain all spilt fluids.

- ELR bypass switch (activated by key only): Turn off ELR to avoid nuisance tripping when powering electrical motor, or other similar equipment.

- Engine oil drain pump: Reducing service time.

Technical Specifications PRAMAC Off Grid LX LFP:

- Power output (continuous): 60 kVA

- Peak power (5s): 120 kW

- Voltage: 400/230 V

- Frequency: 50 Hz

- Phases: 3

- Battery specifications Battery (type): Li-Ion LFP

- Nominal battery voltage: 48V

- Battery life (at 90% DoD): 6000 cycles

- Nominal battery capacity (size): 96kWh

- AC-side usable energy (@90% DoD): 82kWh System throughput: 125A

- Length (L): 2240mm, Width (W): 1160mm, Height (H): 2018mm, Weight: 2250kg

- Discharge temperature range: -10...45 °C

- Charging temperature range: 0...45 °C

- Inverter protection: short circuit, overload, overtemperature.

Telematics

All our vehicles have the capability to remotely download telematics; providing instant details of mileage, fuel usage, CO2 emissions, and GPS location.

This is information that we can provide as a report to your Production.

It also allows Translux to effectively and efficiently plan routes for all of your trailer movements, optimising driver and truck usage, whilst reducing fuel consumption and emissions.

Solar

At Translux, we offer solar-powered Honeywagons and School Room Trailers - these are not only self-powered, but are small enough to reach your most challenging locations, ensuring peace of mind that the basic facilities are covered.

Recycled, reclaimed & reused

We aim to ensure that any builds and repairs carried out by our trailer manufacturers are done so using exclusively recycled, reclaimed, or reused materials where possible.

Example Components & the Materials We Use

- Our chassis use recycled steel.

- Our laminated side walls use recycled aluminium tubing and foam insulation.

- Our wall slide-out flooring is reclaimed and reused.

- Our roof structure wood panels are reclaimed.

- Our cabinet doors are made from recycled MDF materials.

- All plastic components that we use are recycled and/or reclaimed.

Our Assisted Access Fleet

We have worked hard on our fleet to ensure that all cast and crew feel included whilst at work, and we proudly offer the following assisted access vehicles (which are all accessible either by lift or ramp):

- Costume Artics

- Make-up Trailers

- Single-Artist Trailers

- Production Offices

- 2-Ways

- Dining Buses

- Honeywagons

Being able to provide accessible options not only meets what should be industry-standard criteria (an issue we helped highlight by working alongside the TV Access Project), but also negates the need to hire additional trailers to meet such needs. This in-turn reduces mileage, costs, and the environmental impact of Production.

Founded in 2011, ALBERT support the Film & Television industry to reduce the environmental impacts of Production and to create content that supports a vision for a sustainable future.

The BAFTA Albert Suppliers Directory is the go-to resource for any Production looking to reduce its environmental impact by working with sustainable suppliers for the Film & Television Industry.

Translux has proudly passed Albert’s rigorous vetting process, affirming our Company’s commitment to sustainability.

Key points about our offices, depots & trailers.

PLASTIC POLICY & AUDIT

Our single use plastic policy is available for all staff, a copy can be sent to Production if required. We also regularly undertake a single-use plastic audit.

RECYCLING

All staff and visitors are encouraged to use our recycling and waste bins across all our offices and depots.

REGO CERTIFICATED

All our offices and depots are REGO Certified, meaning a proportion of electricity used is produced from renewable sources.

INVESTMENT

We have heavily invested in technology, to enable all staff (at each office and depots) to partake in remote meetings, reducing our CO2 Emissions by over half their previous monitored levels.

ELECTRIC VEHICLES

We have provided a large percentage of our staff (across our offices and depots) with EVs to enable their travel to be emission free.

TRAILER LIGHTING

All our trailers have LED lighting throughout.

PUBLIC TRANSPORT

Our Head Office is located less than 1 mile from the nearest mainline train station making commuting possible for staff, drivers, and visitors alike.

CYCLE TO WORK SCHEME

We offer all our employees access to the government Cycle to Work Initiative (in addition to this, we offer lockers and shower facilities).

PAPER USAGE

We introduced a scheme to reduce our printing, with goal of becoming a paperless office by March 2026 – this is currently being rolled out across all offices.

LOCAL SUPPLIERS

We pride ourselves on working with local suppliers, who in turn employ local people; not only for our social governance, but further reducing delivery and collection mileage.

CLEANING

The cleaning products used in our washroom facilities are Eco-Friendly, and where relevant are formaldehyde free.

LOCATIONS

Our Head Office, UK regional hubs, and European regional hubs, are well-positioned to service all major Studios efficiently, thus lowering travel-time, mileage, and overall emissions.

Builds

Creating beautiful bespoke finishes, at a fraction of the cost, with a circular economy in mind.

REUSE:

We understand the film and television industry is hard-hitting and fast-paced, and takes cast and crew to remote locations in all weathers. With the need for durability in mind, we choose the highest quality materials when constructing our trailers so that the teams using them can rely on them over, and over again.

REPAIR:

We know that things don’t always go to plan, and occasionally things get damaged. Our specialist repair team ensure that if something requires a bit of TLC to keep it working, they will take the time to repair it, preventing it from ending up in the landfill.

RECYCLE:

All good things may indeed come to an end, but that doesn’t always truly mean "roll credits". If we can no longer repair something, the materials, fabrics, and parts will be taken and used elsewhere, giving them a new lease of life in another guise.

Driver Training

A sensible, safe and courteous driver is what you can expect each time from Translux

IN-HOUSE

With our in-house driver training programme we can ensure that anyone that drives for Translux understands our ethos and our requirements.

IN-DEPTH

During their in-depth assessment each drivers will learn that their actions behind the wheel have both an environmental and social impact.

INCLUDED

The accredited Driver CPC Fuel Efficiency Training Programme includes the effects of heavy braking, idling and smooth acceleration, as well as showing respect to other road users, members of Production and the Studios/locations you are working at.

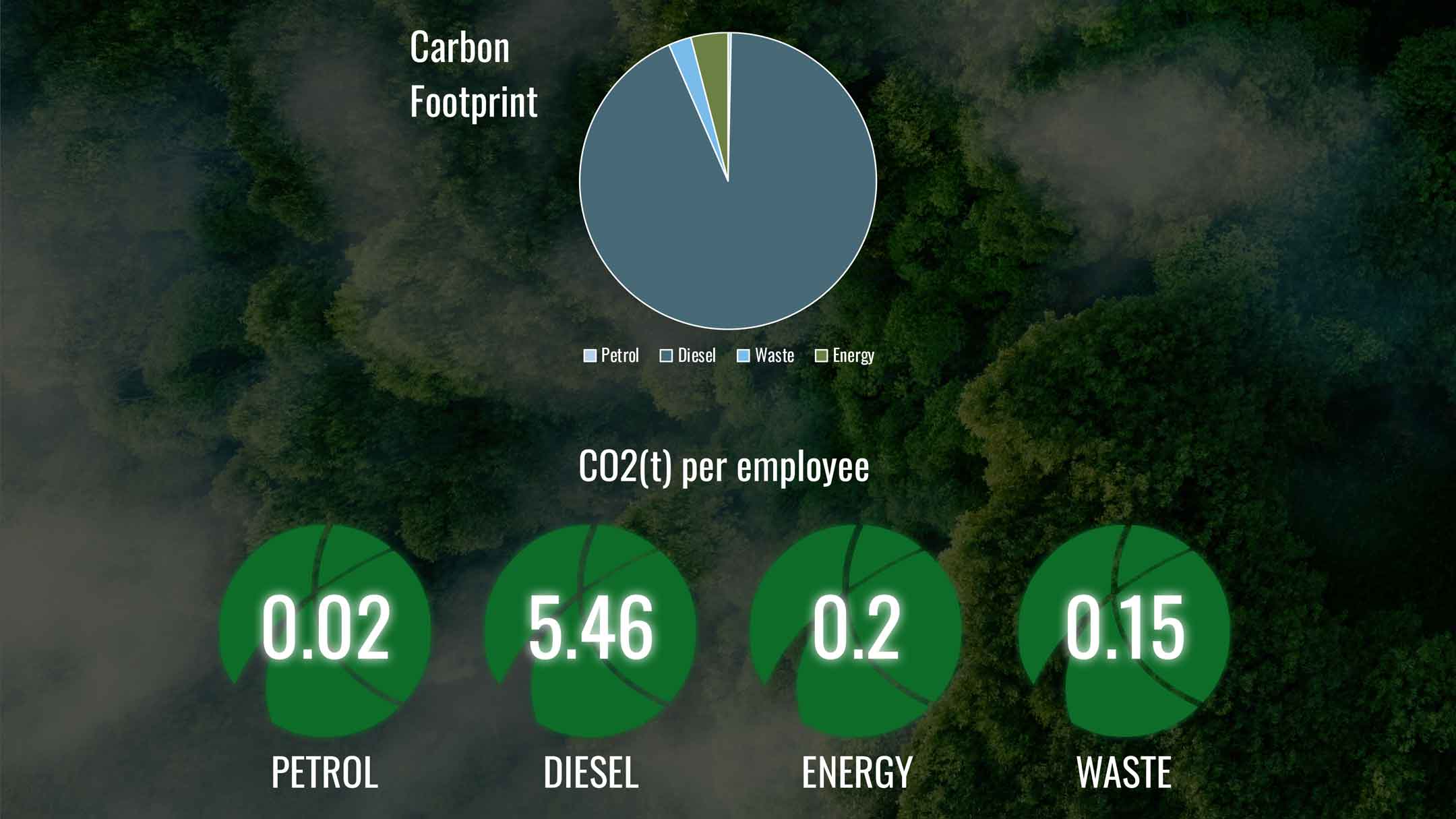

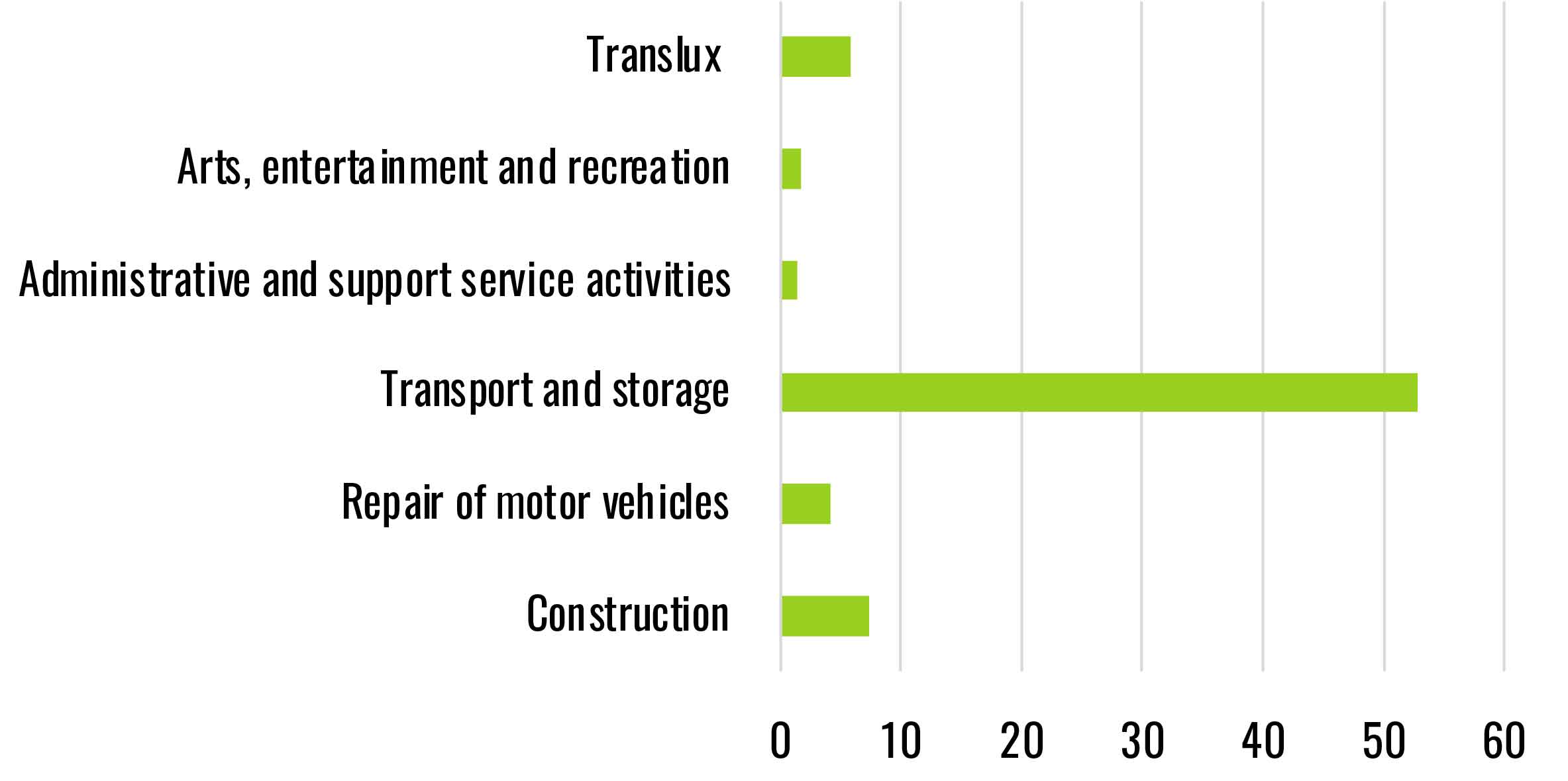

Carbon footprint comparison

Our Wider Reach

The Duke of Edinburgh Award Scheme inspires hundreds of thousands of young people to explore who they are, grow in confidence and develop the skills they need to successfully navigate life.

Translux supports local litter-picking, sponsoring young people as they work towards achieving their bronze and silver awards.

Film London launched The Fuel Project, a report providing practical information, steps and support to Film and Television Production suppliers as they transition to new, low-carbon technologies, and help reduce emissions in the industry.

Understanding the importance of information and transparency, Translux proudly contributed to the project, providing invaluable data and insights into operational activities.

Our other work

"One honey wagon cannot service an entire industry."

The 2021 Underlying Health Condition Report found "a sheer lack of any accessible facilities available." After surveying facilities companies within the Film & Television Industry, just one company was able to provide a single wheelchair accessible honey wagon (that’s film-speak for a washroom/toilet), whilst half of the companies surveyed (who have fleets of hundreds of vehicles) had just one, if any, accessible trailers to offer. As the report succinctly put, "One honey wagon cannot service an entire industry."

As the leading facilities provider in the UK and Europe, we at Translux, realised we needed to lead by example and do more. Actions speak louder than words, so we decided to show the industry how things should be done.

We began by building the industry’s first fully accessible luxury slide-out cast trailer, complete with electronically adjustable shelves and tables, voice operated wireless assistant, and fully accessible washroom to name but a few of its features. We followed this with accessible Honeywagons, Dining buses, 2Ways, Production Offices, MakeUp Trailers and Costume Trailers, with many more in development as we continue towards our goal of providing fully accessible unit bases.

Our focus on accessibility, and reputation as the most forward-thinking facilities company in the country, led to us being hand selected by the TV Access Project (TAP) to lead and help set the standards regarding the accessibility issues the industry currently faces.

We created blueprints to educate and help companies as we work towards a more accessible and inclusive industry. The blueprints, produced by TAP, contain suggested changes that can be made to facility vehicles and act as a guide for companies within the industry to follow. The TAP blueprints are available here.

We know there are still many things the industry needs to do to accomplish its accessibility goals, but we are immensely proud by the measures taken thus far, and are honoured to have played such an integral part in these early stages.

The future certainly looks bright, and Translux will continue to lead the way as the industry continues to improve accessibility and inclusivity for all.

Protecting Habitats Acre by Acre

Habitat loss is the greatest threat facing wildlife worldwide.

We believe that by protecting land, acre by acre, we are taking the best action to ensure a future for wildlife.

With our support, The World Land Trust have purchased acres of habitat to protect wildlife in perpetuity.

Protecting Habitats Acre by Acre

With our support, The World Land Trust have purchased acres of habitat to help ensure a safe and permanent home for the world’s wildlife.

KENYA - Dakatcha Woodland

This woodland encompasses important tracts of the evergreen forest species Cynometra webberi and areas of seasonal wetlands, crucial for the breeding population of an endangered bird – Clarke’s Weaver (Ploceus Golandi) – not known to nest anywhere else.

SOUTH AFRICA - Renosterveld

A three-hour drive east of Cape Town lies the last 5% of one of Earth’s most threatened habitats. This is a place so unique, it falls within the smallest, and richest (relative to size) of Earth’s six Floral Kingdoms. This is the home of over 500 plant species, as well as threatened birds and charismatic mammals.

ARGENTINA - Somuncura Plateau

Set within Argentina’s Río Negro province, residents include the El Rincon Stream Frog, a species part of Zoological Society of London’s TOP 100 EDGE worldwide ranking of extinction-facing amphibians; the Naked Characin, a symbolic species in Argentina; and two endemic freshwater snails who are likely to be rated as Critically Endangered.

Toilet Twinning

We are twinning our Honeywagons with various locations around the World by working with Tear Fund. This work has helped bring safe water and transformed the lives of families and even entire villages.

For every toilet we twin, Tear Fund work closely with local teams to support sustainable access to decent toilets, safe drinking water, and healthy hygiene for people affected by this urgent crisis.

Protecting Our Biodiversity

At all our Translux offices and depots, we try to protect and encourage the area’s natural biodiversity. Our use of pre-existing sites (be that former construction sites or industrial areas for example) ensures that we limit the footprint and impact we have on the local environment.

This approach to operations helps us protect our biodiversity as hedgerows, scrub, foliage and other habitats are left untouched.

Our hedgerows provide food, shelter and nesting sites for wildlife and flood attenuation. Reduced hedgerow cutting to allow hedges to grow wider, denser and taller with some standard trees.

This results in an increase in flowers, fruits and nuts which are important resources for pollinators (as well as a wide range of other invertebrates), birds and small mammals.

Our hedgerows act as important wildlife corridors as well as providing homes for a wide variety of wildlife.

Scrub provides nectar, seeds, fruits, shelter and nest sites for invertebrates, birds and mammals, creating a mosaic of habitats and greater structural diversity, which increases biodiversity.

Ivy blossom is visited by high numbers of bees, butterflies and other invertebrates and provides shelter and cover during winter months. Ivy is the single most important nectar source for the Ivy Bee, a colonial species of solitary bee that has now become well established in southern England. The berries and foliage are important food for many animals with some species particularly associated with ivy (e.g. Holly Blue butterfly and numerous moth species).

Summary

We believe that by working with Translux on your next Film or Television Production, you will be joining into a partnership of progress and innovation.

With our aim to deliver sustainable solutions throughout your shoot, you can rest assured that Translux; its staff, trailers and vehicles, not only support your Production, but your sustainability needs also.

Translux – providing luxury with principles.

Contact us

Please choose how you would like to get in touch.

You can either email us at sales@translux.com or give us a call on +44 (0)1494 520050

If you’re unavailable now, please simply enter your details below and we will contact you.